Blogs

If you would like to find out more about how a servo driver operates, then here’s your place! At SIMTACH, we're passionate about technology and we love to delve into how things work. In this article, we’ll be discussing the ins-and-out of servo drivers and how they aid in motion control of motors.

What is a servo driver and how does it work ?

A servo driver is a compact but capable device that assists motor speed and position control. It does so by listening to signals from a controller and transmitting commands to the motor in accordance with those signals. This lets the motor have precise movement control and is appropriate for applications which demand high accuracy of positioning.

What is Servo Driver and How to Use It?

A servo driver consists of a number of subsystems that combine to manage the motor. Those things include a power supply, a control circuit and an amplifier. The driver is fuelled by the power supply, whereas all input signals are processed in a control circuit and go to give orders to the motor. The amplifier then amplifies these commands to provide the motor with the power necessary to operate effectively.

An analysis of the signals and my feedback loops that can be enabled for operation on a servo driver.

The servo drivers use a feedback system to maintain a smooth operation. The control system transmits instructions to the driver, informing it how fast and in which direction it should drive the motor. The driver thus uses feedback loops to verify the motor move is occurring as desired. If not, the driver will have to fiddle to drive back the motor in place because my arm is done.

How servo drivers enable motor speed and position control/ regulation.

Servo drivers are an important part of what regulates the speed and position of motors. They make certain the motor runs at the proper speed and stops in the right position, which is crucial for tasks that demand accuracy. Servo drivers control the performance of the motor and ensure that it conforms to specifications by trimming commands sent to the motor.

Explore the most recent evolution of servo driver technology.

With the evolution of technology, servo driver configurations and functionalities are also changing. I'd like to see them HPs outdo themselves and keep pushing the limits while improving upon reliability and capabilities of these servo drivers. Newer features that some these models have include built-in control systems, remote signalling and wireless communication. All these improvements contribute to making servo drivers even more reliable and powerful instrument for motor control.

SUMMARY OF THE INVENTION Generally, servo drivers are employed to control motors and cause them to run accurately or smoothly. Through seeing the application and function of servo drivers, we can see why they are such an important part of motor control in a number of industries. As design and performance progress, modern servo drivers are expected to become more efficient and have greater capabilities. At SIMTACH we are thrilled to be taking this revolution forward and expanding into the universe of servo drivers and technology.

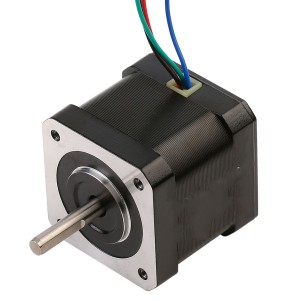

INDUSTRIAL APPLICATIONS: The stepper motor is widely used in many machines and equipment for controlling the movement. They make small, measured movements in order to be positioned exactly where they need to be. But, there is also a type of stepper motor known as a closed-loop stepper motor that provides even more exactitude and accuracy. Let’s take a look at how some of these differences stack up, and why industries are shifting from using regular stepper motors to close-loop stepper motors.

Stepper motors vs the closed-loop stepper motors

Stepper motors work by receiving electrical impulses to move in exact settings. There are no feedback mechanisms to tell whether the follower has reached the correct place or not. On the contrary, a closed-loop stepper motor has feedback sensors that inform the controller how it is doing by having an accurate way of getting to its position. This feedback loop provides more precise control and precision in a closed-loop stepper compared to an open-loop stepper.

What’s so good about closed-loop stepper motors anyway?

Limits to the number of steps can also be quite high in closed-loop stepper motors. One side-effect is that of increased accuracy. As it gets regular feedback on its status, a closed-loop stepper motor has the ability to change the way it moves in real-time so that it will reach that position exactly. This means that closed-loop stepper motors are suitable for tasks where accuracy is crucial, for example in robotics and automation.

Improved reliability is also another benefit of closed-loop stepper motors. Since they are able to sense errors and rectify it on spot, closed-loop stepper motors hardly ever lose steps or stall. This leads to increased and stable operation, minimizing chances of breakdowns and maintenance costs.

Why closed-loop stepper motors are the solution for achieving accuracy and precision

It is the tec It is the technology of closed-loop stepper motors that differentiates them from standard stepper motors. Closed-loop step motors have encoders or resolvers that continually feedback to the drive the position of the motor. This feedback is regularly sent to the motor controller, where it's compared with the target position and adjustments are made to exact movement.

By staying as in touch with itself as it possibly can, a closed-loop stepper motor is able to plan for the differing factors that may result from different loads or outside forces. With the power of real-time adaptability, closed-loop stepper motors can remain on their target position even under difficult circumstances.

Use of closed loop stepper motors in different industries

Closed-loop stepper motors are found in many industries where precise control is required. For instance, within the field of mobility (medical), closed loop stepper motors are utilized in robotic surgery systems to carry out complex operations with great precision. In the aerospace field, a closed-loop stepper motor can be applied to flight control system so as to assure the stability and safety of airplane.

In the industrial sector, these are used in CNC machines which cut and shape materials to produce a final product. Manufacturers can also get tight tolerances and uniform quality by using closed-loop stepper motors.

In general, closed-loop stepper motors have many advantages over conventional stepper motors in terms of precision, reliability and flexibility. Due to their advanced technology and accurate control, closed-loop stepper motors are more and more used in a plethora of industries that demand high precision and performance.

Ball screws are a fundamental component of most machines that utilize linear motion. If you’re in a position where you have to pick the right ball screw for your job, some of the things you need to consider are what we’ll be discussing here today— in this guide on how to choose a ball screw, we will discuss: A basic overview of what isn’t so much known as it is understood about ball screws Factors to think about when needing and wanting to know how the process and the consideration that needs to be taken or placed into deciding upon a specific type How many types of ball screws there actually are Tips on picking out which one might just work perfectly What little tricks can net incredibly solid results from Your choice in all and anything revolving around ball screws lots more too!

Ball Screw Basics explained Forgery Token

Ball screws is about the mechanism of a conversion of rotation motion into a linear one. They are used in machinery such as CNC machines, robots and other automatic systems. Ball Screw The ball screw is a high efficiency feed screw with the ball making a rolling motion between the screw axis and nut. The balls help lower the friction and thus make the movement smoother and more efficient.

Considerations For Selecting Ball Screws

There’s a lot to consider when choosing your linear motion system’s ball screw. These include those related to load capacity, speed, accuracy and general performance of your application. You’ll also consider the screw’s length and diameter, along with its pitch (the amount you feed the screw for one rotation). You also have to take into account the environment in which the ball screw will run, including temperature, dust and humidity.

Ball Screws - Nut Varieties Compared

There are many different kinds of ball screws, but all of them fall into one of these two categories. A few of the more popular forms are precision ground ball screws, rolled ball screws and miniature ball screws. Ground ball screws are known for high accuracy and precision, while rolled ball screws make more economic sense and generally perform better than standard acme used in some applications. Additionally, miniature ball screws are less bulky and ideal to use where space is at a premium. You could get the suitable ball screw type that meets your requirements.

How to Choose the Best Ball Screw for Your Application

How to Choose the Best Ball Screw for Your Application: Understand Your Requirements and Outcomes Perhaps you are interested in the right ball screw, how do you even start? Take the weight capacity, velocity, accuracy and environment for your project in consideration. You may not know exactly what type of ball screw you need to purchase, but a knowledgeable engineer or supplier will be able to help guide you through the process and make sure that you get what you need. The Maintenace and life of the ball screw should also measure for long time working.

Getting the Most from Ball Screws with the Proper Selection

After you’ve chosen the best ball screw for your linear motion system, there are a number of things that can help ensure optimal performance. Periodic lubrication and maintenance are necessary to maintain working condition. You should track the ball screw temperature and vibration in order to pick up any potential issue early. By selecting the proper ball screw and maintaining it appropriately, you can guarantee your linear motion system will be both effective and efficient for a long time in use.

In summary, choosing the correct ball screw for your linear motion system is a critical component to get the best performance and efficiency. Understanding the fundamentals of ball screws, taking key factors into consideration, working with vendors on comparisons among different types of ball screws and accessories such as nuts and bearing supports based on assembly specifications, applying some practical tips throughout testing to improve results, and optimizing screw performance will help ensure you select the ball screw that’s right for your application. 16.Up cbn grinding wheel Remember to select SIMTACH for your entire ball screw requirements and enjoy smooth linear motion with high precision!

Poultry farmers face unique challenges: ensuring a clean, durable, and easy-to-maintain environment for their flocks. Steel structure has become the preferred choice for poultry houses, and Bao-Wu (Tianjin) Import & Export Co., Ltd. is leading the way in supplying high-quality steel materials for this sector.

Steel structure poultry houses offer several advantages over traditional wood or concrete structures. They are resistant to rot, pests, and corrosion—thanks to Bao-Wu (Tianjin)’s galvanized steel and stainless steel products. The material’s durability means the poultry house has a longer lifespan, while its smooth surfaces make cleaning and disinfection easier, reducing the risk of disease. Additionally, steel structures are quick to assemble, allowing farmers to expand their operations faster.

Bao-Wu (Tianjin)’s experience in serving 60+ countries and 200+ cooperative enterprises means they understand global poultry farming needs. From customized steel frames to anti-corrosion roofing sheets, they provide all the components required for a high-performance poultry house. Discover their poultry house steel solutions at https://www.wswlh.com/

How Automated Power Hammers Help Achieve Perfect Forging Temperatures in Alloy 825

By traspino, 2025-09-28

Forging Alloy 825 with Automatic Power Hammers

Read also: Forging is a process of forming metal into different forms using heat and pressure. Another such important metal that is commonly forged is Alloy 825, a robust and resistant-to-corrosion material. For the optimal temperatures required to forge Alloy 825, automated power hammers are instrumental.

Contribution of the Power Hammers With Automated Control into Alloy 825 Treatment

A celebrity in certain circles, and players find men with power tools sexy; a tiny woman with an industrial-size hammer simply blows their minds.918-453-1445Power hammer operationAutomated power hammers are metalshaping machines that add controlled force to hot metal as it is being worked. In the case of Alloy 825, they are needed in order to create just the right temperature and pressure to forge. The use of machine power hammers guarantees that the Alloy 825 is properly shaped and formed.

Automation Power Hammers are Transforming Forging in Alloy 825

Impact presses can produce the necessary amount of heat and pressure needed to work Alloy 825. Equipment"In particular, this equipment provides a process in which heat treating workpieces after the forging of an outer member becomes unnecessary to such an extent that heat-treating is done all over." Even with an automated power hammer it would be more difficult to reach the necessary temperatures for forging Alloy 825.

Why Use an Automated Power Hammer for Alloy 825 Alloy Temperatures

Another advantage of Alloy 825 forging with an automatic hammer is that temperatures can be maintained within precise boundaries. This is critical not only due to Alloy 825 needing a certain level of heat to be shaped properly. Automated power hammers can be monitored and adjusted to maintain the right temperatures throughout forging.

How Alloy 825 Forging Processes Benefit from Automated Power Hammers

Automated power hammers also help accelerate the forging of Alloy 825 besides regulation in temperature. These machines have been designed to work fast and efficiently, with the purpose of saving time and resources for producers. The use of mechanised/application driven power hammers is a cheaper and more efficient way of forging Alloy 825 with improvements in the quality of the final forged product.

In summary, automated power hammers are essential tools for obtaining just the right forging temperatures with Alloy 825. These machines enhance the forging process, as they can control and monitor temperature and pressure levels to create strong products. Phoenix Alloy is committed to enhancing the production of Alloy 825 and supplying high quality products for customers. With the application of these modern machines, Phoenix Alloy always can make sure the high quality for Alloy 825 forging products in every process.

How Nickel Alloy Manufacturers Achieve 99.9% Pure Metal Through Precise Smelting

By traspino, 2025-09-28

Nickel alloys are exotic metal forms that are created by combining nickel with other types of materials, specifically what are known as reactive metals. Phoenix Alloy is the most professional company. It manages all manners of nickel alloys very well so that there is quality production in the end. One of the ways they do this is to smelt nickel alloys to 99.9% pure metal, using a combination of exact precision methods.

The painstaking task of smelting nickel alloys as pure as possible

Smelting is melting metals that are combined together to form new ones. This holds particularly true for Nickel Alloy 718 , as the alloy purity might influence its properties. Phoenix Alloy employs state of the art equipment to refine melt practices. To do so, they first set out precise amounts of nickel and other elements to make the intended alloy. Then, the metals are heated to high working temperatures in a controlled environment to guarantee that they melt together entirely. This elaborate procedure helps Phoenix Alloy to obtain a high degree of purity in their nickel alloys.

Precision temperature control and the use of select metals result in a superb quality.

Temperature regulation is vital during the smelting of nickel alloys. If the temperature is not hot enough, the metals will not achieve full melting which creates impurities as a result. Too high a temperature may provide an environment where the metals negatively interact and thus degrade alloy quality. The temperature of meling in the smelting process is controlled by advanced techniques. They’re also careful to control the alloy’s composition so that it meets exacting strength, corrosion-resistance and other requirements. It’s by focusing on these details that Phoenix Alloy is able to produce high quality nickel alloys.

The importance of high technology in the manufacture of 99.9% purity nickel alloys

High-tech is essential to manufacturing top-grade nickel alloys. Phoenix Alloy is committed to advanced process monitoring and control through the use of technologically-advanced equipment. That means sophisticated heating systems, accurate measuring devices and computerized controls to make sure the metals are melded together just right. Using technology also permits Phoenix Alloy to fine-tune our methods so we can mix the way we want to for efficiency and consistency. With the integration of innovative technologies into traditional metal smelting process, we have developed a series of high purity Nickel Alloys up to 99.9%.

Quality control of nickel alloy production in the strict sense for better effectiveness

Aside from state-of-the-art technology, Phoenix Alloy has stringent quality control systems to make sure their nickel based alloys are of superior quality. They're physically checking so they can pass them through tests/inspections for impurities or defects that occur when the metal is heated. If they find something wrong, they immediately fix it. These details as well as commitment to quality control allow Phoenix Alloy to make high performing nickel alloys that are above the industry standard.

The fine art and science of smelting nickel alloys for maximum purity

Smelting nickel alloys is an art. It is a process that requires incredible knowledge of metallurgy, chemistry and physics and skilled hands to work with the metals. Phoenix Alloy joins their experience in these areas with their dedication to quality, delivering nickel alloys that are of exceptional purity and the highest standard of integrity. Through continuous improvement on equipment and technology, the quality of products is ensured by Phoenix Alloy well-controlled system.

In summary, Phoenix Alloy is a high-tech enterprise dedicated to developing and producing special Nickel Alloy 625 , with 99.9% purity smelting process perfected. With precise temperature, composition and other parameters in the smelting process that they control themselves, they can produce extraordinarily high-quality alloys. Nickel Alloys - Products are manufactured with superior equipment, One of the most strict quality control system and our products are known for its unique design, high purity and best performance. We pride ourselves on being a trusted source for high-quality metals across the board.

How Nickel Alloys are Shaped into Metals We can form and shape our specialist materials using two machines; Cold Forming and Hot Forming Machine. These devices streamline and enhance the process. We will be studying what role Cold and Hot Forming Machines play when it comes to shaping Nickel Alloys in a proper way.

Scanning the production of Nickel Alloys by Cold and Hot Working

Cold forming is a type of forging process, where Nickel Alloy 718 are shaped at room temperature. With hot forming, on the other hand, Nickel Alloys are heated prior to being formed. Both methodologies are advantageous and applied based on the desirable result to be obtained.

Optimizing Efficiency with Cold and Hot Forming Equipment for Nickel Alloys

Cold Hot Forming Machinery aids in improving productivity with automation of the forming operation. These would machines are designed to produce nickel alloys quickly and accurately, the saving that this process will generally achieve is substantial. These machines assist workers in making Nickel Alloy shapes at a faster rate.

Accomplishing Meticulous and Consistent Forming of Nickel Alloys using Machinery

One main advantage that Cold and Hot Forming Machinery provides is the possibility to produce Nickel Alloys shapes precisely and in a constant manner. These are machines that can form Nickel Alloys to the exact size and shape they need every time. This ensures that the end result is of a good quality and fit for purpose.

COLD AND HOT FORMING OF NICKEL ALLOYS TO INCREASE MATERIAL PROPERTIES

Nickel Alloys also gets benefits from Cold and Hot Forming innovations. By utilizing these methods to process Nickel Alloy 625 , we are able to enhance their strength, hardness and resistance to corrosion. This enables use in an array of applications across various industries.

Discovering the Adaptability of Cold and Hot Forming Machine For Nickel Alloys

Cold Hot Forming Machines are 'all-purpose' – they can produce Nickel Alloys in any design (pipe, tube, sheet, wire). This flexibility renders the machines indispensable in sectors with heavy use of Nickel Alloys. They can be tailored to form Nickel Alloys in diverse forms which is useful to the fabricators.

Summary: Cold & Hot Forming Nickel Alloys is not an easy material to machine and special process such as cold and hot working are required to achive the economic removal of material from the raw forged billet. When we take a look at the operations, efficiency maximization, precision and uniformity of all these processes as well as property improvement, and utility are the explanations on why these machines are also vital for Nickel Alloys. Nickel Alloys have been easier to shape and form with Phoenix Alloy’s Cold and Hot Forming Machinery, gvor resulting in high-end products that conform to industry standards.

Delivering Reliable Nickel Alloy Quality Reports with PT, UT, and Advanced Inspection Methods

By traspino, 2025-09-28

Nickel Alloys: In the Realm of Alloys, nickel counts as another mighty element. Such exotic metals have high strength, resistance to corrosion and high temperature properties. Quality and integrity of nickel alloy subcomponents requires advanced techniques for examination. As a supplier, Phoenix Alloy is widely used in quality nickel alloy report ability to provide test reports such as PT (Penetrant Testing), UT (Ultrasonic Testing) and other advanced inspection.

Improve the Quality of Nickel Alloys with Advanced Inspection Methods

Nickel Alloy Quality Advanced Inspection Techniques are Key Inspect When Ramping Up to High-Quality Alloys Concerning improving Nickel Alloy 718 quality, advanced inspection techniques are critical. These techniques are also well-suited to detect any internal cracks and blemishes in the material, beyond simple visual inspections. Including PT, UT and other high-end methods help investigators guarantee that nickel alloys are of the best quality possible. And here at Phoenix Alloy we’re proud to be a step ahead in adopting these state-of-the-art inspection methods.

The Place for PT, UT & Advanced Techniques on Ni Alloy Quality Reports

PT, UT and NDE advanced methods are key-controls for the generation of nickel alloy quality certificate. PT is a method in which the surface of the material is coated with a liquid penetrant that can detect surface-breaking defects. UT, meanwhile, utilises high-frequency sound waves to identify inernal defects within the metal. With the use of these methods and sophisticated inspection practices, Phoenix Alloy is able to provide detailed quality reports which offers customers reliefs.

Obtaining Consistent Quality of Nickel Alloys on Reporting with PT and UT Examination

Careful examination is essential for successful reporting of the quality of Nickel Alloy 625 . Both PT and UT are unviolable stages in the process. PT can find small surface defects but be invisible to the naked eye; UT can identify hidden cracks in the inside of the workpiece. It means one of the following: With these tests phoenix-alloy ensures that our nickel alloys meet the most stringent quality standards.

Advancements in Accurate Nickel Alloy Quality Reporting Made Possible Through New Inspection Techniques

Advancements in inspection technology have changed the dynamic for nickel alloy quality reporting. New tools such as digital imaging and automated testing systems have now made this more efficient than in the past. Phoenix Alloy is continually searching for new techniques to upgrade their inspecting technology in order to supply customers with the most accurate quality report available.

Quality and Integrity with PT, UT, and Advanced Inspection of Nickel Alloys

Finally, the quality and integrity of Nickel Alloys must be manged via a combination of PT, UT, and other advanced inspection technologies. Through the introduction of these techniques, Phoenix Alloy is showing the world that they are investing in products which will continue to exceed industry requirements well into the future. With its constant innovation and commitment to excellence, Phoenix Alloy set the benchmark for nickel alloy quality reports.

How to choose different drill bits for rotary drilling rigs when dealing with different rock formations and geological conditions?

By traspino, 2025-09-28

When using rotary drilling rigs in different locations, it is necessary to select the right drill bits. The rock and ground conditions can determine which drill bit is most suitable. At Hunan Outai International Trading, we are professionals who want to be sure you know which drill bit is going to work out the best for your project.

The effect of rock formations on drill bits.

You need different drill bits for different types of rock formations. For instance: soft rock like limestone will need a different drill bit than tough hard rock like granite. It’s important to understand what type of rock you will be drilling through, so that you pick the right drill bit.

Adjusting bit selection for different formation types

It’s not just about what type of rock you’re dealing with either, the overall geology of an area is crucial to take into account when drilling for water. For instance, if the ground is mostly loose dirt or gravel, you will require a different drill bits than if the hole will be drilled into solid rock. Taking into consideration that the bore site is specific to the geology at a given location will help you select the best drill bit for any project.

What to Consider When you're looking for rotary drill bits

There are several important factors to consider when choosing the right drilling tool for your application. These may include the type of rock you are drilling, the hardness of the rock, how big a hole you need to drill, and how deep in the earth you will be drilling. By taking these factors into account, you can select the right drill bit that will work well for your particular project.

Matching the rock drill bite to the hardness of rocks

How hard the rock you are drilling into, will greatly determine what type of drill bit to use. For instance if you’re drilling a hole in soft rock you will require drill bit with sharp teeth that can slice through the rock. Conversely if you are drilling into hard rock, you will require a drill bit with teeth that are tough and able to withstand all the challenging conditions.

Ways to be maximising your drilling with correct drill bit selection

To get the greatest performance from your tool, simply choose the one that best meets your needs with precision and durability and you will see for yourself that it is one of the most useful bits in any professional's toolbox. TIP: To get the most out of drilling, Inspect and maintain your drill bits . It's also crucial to select the right drill bit for the types of rock that you will be drilling in. These guidelines will help ensure that you get the most productivity and efficiency from your own rotary drilling rig.

In a word, selecting the proper drill bits for rotary drilling rig is very important in various types of rock formations and geological environments. Drill Bit Selection Against Rock Formations Tailored drill bit choices are made against different geological conditions Considerations when selecting a drill bit Match the hardness of rock formations to suitably matched drilling bits Maximize the drilled performance with customized drill bit selection Ultimately, take your drilling project to become possible success With above guide you will drill like a dive master. At Hunan Outai International Trading Co., Ltd, we have a variety of superior drill bits to support your drilling applications. Get in touch with us today and we’ll discuss how our services can help you select the right drill bits for all your drilling needs.

Why are "fan-shaped cakes" suitable for lawn parties? How do they compare to other types of outdoor fireworks?

By traspino, 2025-09-28

Do you know what flies make the perfect treat at your next backyard bash? Let's find out together!

Find out why cakes shaped like fans are the ideal lawn party dessert. Not only are these treats yummy, but they are also easy to eat while you’re out in the grass mingling with friends and family. There are different flavors and colors for everyone to enjoy. And they’re a fun way to sweeten up your outdoor party.

Find out why fan shaped cakes are so great and how they can make a perfect addition to your outdoor shindigresses. What makes these SHUAKIGE cakes special is that it's in a gorgeous fan shape that will surely wow your guests! The brightly colored accents adorning the fireworks cake bring a pop of color to any garden party table. Your friends will fall in love with the beautiful look and yummy taste of these cakes.

Learn why fan-shaped cakes are a safer alternative to regular fireworks for your lawn celebration. Fireworks can be a lot of fun and very exciting, however they are also dangerous if not used safely. Fan cakes, on the other hand, are a responsible and stress-free dessert for al fresco feasting. You can go without any fear on accidents or injuries making them the best choice for family friendly lawn game.

Discover why fan-shaped fireworks cake are an easy and less messy alternative for outdoor events dessert. And unlike most other sorts of confections or fireworks, fan-shaped cakes are nice and neat and easy to serve. And no crumbs or sticky fingers to worry about – just pick up a slice and munch! And, when the party’s over, you can easily clean up without any hassle and with a fan-shaped cake you got convenience on your side for your lawn party.

Check out how fan-shaped cakes can bring flair and visual excitement to your lawn party in a way no other outdoor firework can. Beautiful fan-shaped cakes made according to a time-honored tradition look stunning with their bright-colored, detailed designs -- and are sure to grab attention at a summer gathering. They can light up your law party and add the atmosphere to cheer with your guests. Sprinkle a little sparkle into any outdoor special occasion with Aurora Fireworks fan-shaped cakes!

So as you can see, fan-shaped fireworks cake are just the right lawn-party sweet. They are tasty, great to look at, and convenient + mess free - and perfect for any outdoor party. So why wait? Grab some fanned cakes from Aurora Fireworks and your backyard party will be a night you will never forget!..